How to Sharpen a Machete | CRATEX Abrasives

This article is part of cratex sharpening wheel series.

For full article click here

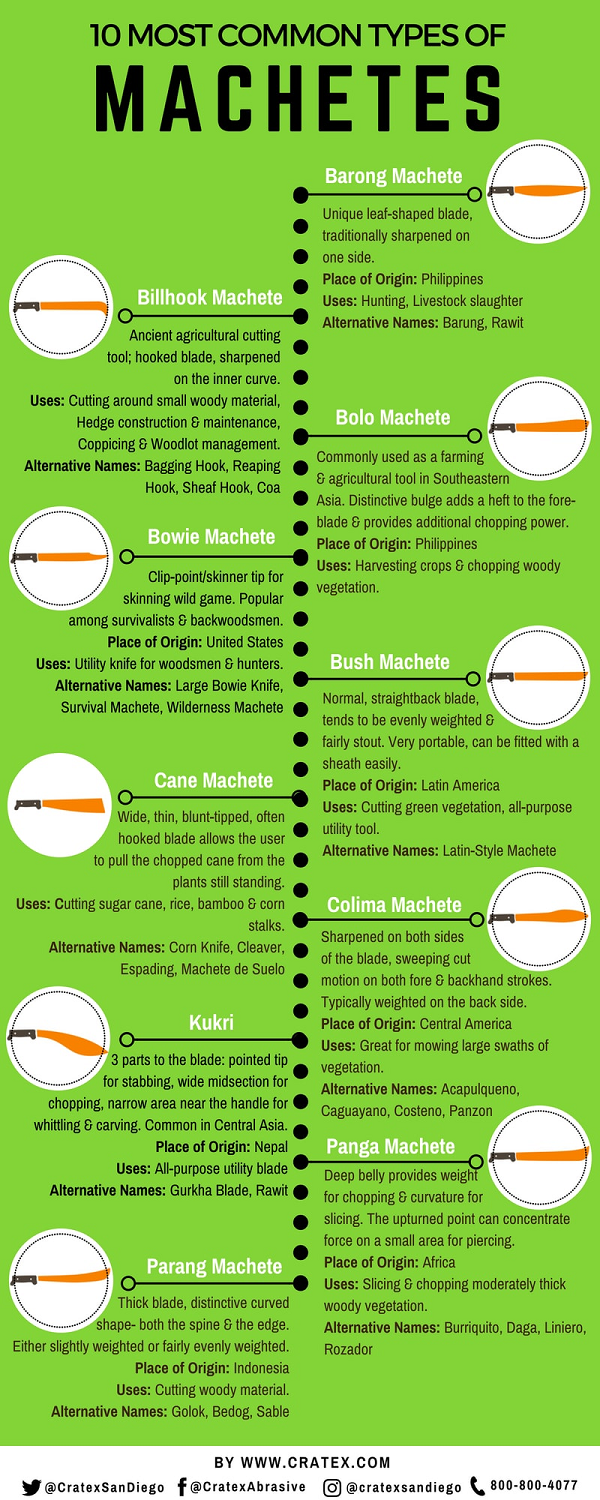

Machete is an amazing tool that has a long history and various applications around the world. People have used it both as a weapon in combat and for protection, and as an agricultural cutting tool.

Today people use it most often for clearing bushes, cutting unwanted branches and other yard or farm work, and for those with survival-in-wilderness thrive, it's an irreplaceable piece of their bushcraft equipment.

You can find all kinds of machetes within all price ranges in both online and in retail so in case you are planning to get one, you'll need to know a bit about different machete blades, types, and most importantly – sharpening methods.

We came up with this chapter after consulting various forums, our community craftsmen and watching a bunch of YouTube videos, so that it could help you find as much details on machete sharpening in one place as possible, help you choose the right machete for you and teach all you newbies about properly maintaining its sharpness. Oh, and we'll present a million-dollar idea for sharpening bushcraft machetes and parangs with CRATEX oblong sticks.

Steel Types Used in Machete Blades

There are three main types of machete blade materials: stainless steel, carbon steel and high carbon steel.

#1 Stainless Steel Machete Blades

Stainless steel is an alloy of iron, chromium (minimum 10.5%), usually nickel, and molybdenum, and a small amount of carbon. Thanks to chromium and molybdenum it is highly resistant to corrosion. The higher the percentage of chromium, the higher the resistance. The purpose of molybdenum is to additionally increase corrosion resistance.

The advantage of stainless steel is that chromium and nickel oxidize and form a protective layer over the steel that prevents rust from developing. Precisely thanks to their rust-resistance, stainless steel blades require far less maintenance than the carbon steel blades to remain in good shape.

The stainless-steel machetes maintain their shinny appearance, so they are ideal for decorative use and display. Regular oiling is not necessary, but you can do it if you want.

The down sides of a stainless-steel blade are that stainless steel is more expensive than carbon steel, and that is not able to take quite as sharp edge as carbon steel. Stainless steel is softer than carbon steel, so it loses the sharpness faster, but can also be re-sharpened more easily, so that's another upside.

Most commonly used in: decorative, ceremonial or display machete blades.

#2 Carbon Steel Machete Blades

The traditional material used for making machete blades, carbon steel,is an alloy of iron and carbon (up to 2.1% by weight). The purpose for adding carbon to iron is to increase the hardness of the alloy.

Higher steel hardness means that the blade holds the edge well, will stay sharper for a longer time, but the higher carbon content will also make the blade more brittle. The increased hardness will also make the carbon steel blade more difficult to re-sharpen, so that's another down side.

Another useful advantage is that carbon steel is cheaper than the stainless steel, but on the other hand, there is one great disadvantage. Namely, the blade is very vulnerable to rust and stains, so it needs to be kept away from moisture and needs to be covered with a light layer of non-detergent oil to prevent rust.

Most commonly used in: blades found in survival and agricultural tools.

#3 High-Carbon Stainless Steel Machete Blades

The idea behind the high-carbon steel is to combine advantages of stainless steel and carbon steel to create a superior material. This steel has higher amount of carbon, so it has the hardness and durability of the carbon steel and has rust-resistant properties of stainless steel. The blades don't discolor or stain while maintaining a sharp edge.

The main disadvantages are the higher price and low tolerance to heat before becoming brittle.

Most commonly used in: both decorative blades and functional cutting tools.

Tip: Store your machetes in a dry place, to prevent the humidity from reaching and damaging the blade. Don't keep it in a sheath when not in field, as moisture can condense inside and rust the blade. If you do wish to keep it there, make sure the inside is well oiled, and check often for rust.

What Angle to Sharpen a Machete

With an exception of machetes like chisel ground sport machetes, machetes are ground on both sides to form a cutting edge. It doesn't require a razor edge, but a chopping edge, since its purpose is to cut through thick bushes, branches and vines. If the blade is too thin, there's a risk that it will break off, and if you make it too thick it's going to be more difficult for the machete to chop into wood.

Since the angle will influence its performance, you'll need to choose it carefully. Smaller sharpening angles of about 20-25 degrees are more suitable for light cutting (e.g. cutting grass, soft vines and non-wood), while heavier chopping tasks (e.g. cutting wood branches) require a larger angle of 25-35 degrees.

If there is danger of hitting nails or if you are working low to the ground, where you can hit rocks and sticks and other similar things, you're going to want to expand the angle out. Generally, anything above 30 degrees will get you into the chopping motion, so for example, 30-32 degrees would be ideal for shopping wood.

Tip: A neat trick to determine a 30-degree angle is to place your little finger on top of the blade. About 2/3 of your little finger width will be what you are looking for.

A lot of people recommend that you shouldn't put a Scandinavian (Scandi) grind on a machete, which is basically creating a V- shape at the end of the edge of the blade. They rather recommend a convex grind, because a Scandi grind delivers less edge strength, since there is less steel at the tip of the blade. Sacrificing sharpness will bring you more durability, so a convex grind is better for chopping.

However, some still prefer a Scandi grind, because it is simpler to do. Putting a good convex grind on a thin blade can be tricky, because it requires things like sandpapering the back with something soft, so it's not suitable when on a survival mission in a jungle.

In any case, you'll be the one to use the tool, you know how you are going to use it, so you'll know which angle is most suitable for your needs.

5 Ways to Sharpen a Machete

Tip: Sharpening a machete is an 80-20 rule – invest 20% of your effort should get the blade 80% sharp enough. Remember: more effort is not needed and is not worth it, because you'll start blunting the blade as soon as you start chopping. That's why getting into a habit of sharpening it often, but quick and easy at the same time.

A lot of machetes sold today have incredibly dull edges that are not suitable for any kind of cutting or chopping, so learning how to sharpen your own machete should be one of your top priorities.

There are many different tools and ways to sharpen a machete, but we'll present the 5 most commonly used methods to help you gain more knowledge and choose faster.

The beauty of learning how to sharpen a machete is that you have plenty of blade to play with - if you mess it up the first couple of times, don't worry, as you can just sharpen it again and again until you get it right.

You have a large blade that you can wear down, so it's difficult to mess up so bad that you'll have to throw the machete away. But hey, if you do - you can find machetes for as low as 10 bucks. Experiment and find a way that is comfortable for you.

Machete Sharpening Tool #1: Belt Sander

The main benefits of using a belt sander are that it requires little effort and little pressure, and that makes maintaining a straight edge extremely easy. The most important thing, though, is not running the blade too quickly on the sander, as the blade will get too hot and the heat can damage carbon steel.

Since it is considered both the easiest method for heavy sharpening, creating a convex utility edge and the fact that you can use just about any belt sender (nothing fancy), it is the most popular tool among many machete sharpeners.

Here are 5 easy steps to sharpen your machete with a belt sander:

- Turn on the sander and grab the machete by the handle with one hand and by the end of the back side of the blade with other;

- Run the machete from tip to heel (easier with vertical bend sander) or from heel to tip (easier with horizontal belt sander) in a slightly arching motion. The arching motion will allow you to sharpen both the tip and the entire blade edge. Repeat several times;

- Flip the machete and repeat the procedure on the other side.

- Rinse and clean and check for a burr by running a piece of paper along each side (the rough sound tells you there is a burr);

- Test the new edge by chopping a 2x4.

Another important factor to consider is the belt grit size when sharpening a machete. The higher the grit, the more time you'll save sharpening, but it also means that you'll shave off a lot of metal, so you'll need to be careful. 80-grit belts are awesome for getting the job done quickly, but you might want to start with lower-grit abrasives until you've become more comfortable with the tool and this sharpening method.

Machete Sharpening Tool #2: Grinding Wheel

This method requires a bit more skills and an experience with operating a bench grinder. It definitely requires more work than the belt sander, and it's not much of a problem for well experienced craftsmen.

Grinding wheels are excellent tools for a more aggressive sharpening in situations where it is necessary to eliminate larger nicks or initial dullness, or for repairing a seriously damaged blade. So, use it for removing initial sharpening, large nicks, rusty spots, spots that have become worn out a bit, but avoid using it for regular sharpening.

Important when working on a bench grinder and with grinding wheels is to always gear up and follow safety instructions . Safety goggles and gloves are most important, so make sure you have some on before you begin. Use a safety guard to prevent the sparks flying towards you.

- Clear up the working space and turn the grinder on;

- Place the tip of the machete in front of the grinding wheel. You can rest the back of the blade on the metal holder to avoid wobble;

- Start pressing it against the wheel. Make sure you are producing one fluid, steady motion and maintaining a consistent angle while running the blade across the grinding wheel. If the motion is not fluid, you won't get an even edge. Repeat a few times;

- Repeat on the other side.

Since grinding creates heat, you'll need to pay attention to rpms. The more rpms, the more heat the wheel will produce on the blade. That will eventually lead to overheating and chipping. You can avoid this problem in two ways: either dip it frequently in a cold-water bucket or use lower-rpm grinders.

Machete Sharpening Tool #3: File

The best thing about this method is that it doesn't require any specialized tools, so it certainly the least expensive method. All you are going to need is a file (you can get one for around $10) and a vise to hold your machete and a little bit of practice.

However, it does require putting some muscle into it, so it's not a preferred choice for those who like things done the easy way.

Important to know is that you are not going to pull the file over the edge nor saw it, since the file teeth point away from the handle, so you'll damage your blade if you do. Instead, you are going to push from the base to the tip of the blade. You'll repeat this motion several dozens of times and repeat on the other side.

There are different vises and ways and sharpen a machete blade with a file, so you'll probably find the way most suitable for you. Here are 3 easy steps to follow for a fast file sharpening:

- Place the handle on top of a block of wood and secure it with a T-vise;

- Slide another block of wood underneath the blade to provide control and stability while you sharpen;

- Place the tip of the file at the base of the blade at the desired angle and slide up, into the blade, from heel to tip with an even pass over the cutting edge. Repeat several times;

- Repeat the same procedure on the other side.

Here's another way to do it:

- Grab the machete with one hand at the back of the blade and hold it down in front of you while holding the file in your other hand;

- Place the tip of the file at the base of the blade on one side at the right angle, as you'll slide the file down;

- Apply a light pressure and draw the file down and over the edge of the blade, going from tip to heel with the file;

- Check for rolled edges with your nails and repeat with a lighter pressure in case there are some imperfections;

- Rotate the machete and hold the tip with one hand, while the handle is pointing downwards. Repeat the procedure.

You can also use a file for light maintenance, and the procedure is pretty much the same as you would do for initial edging.

Machete Sharpening Tool #4: Dremel & Abrasive Bits

Probably not a single craftsman out there that doesn't know about Dremel hand rotary tools. Operating the tool is quite easy: your either hold the rotary tool in one hand and the machete in other, or you secure the machete in a vise to free the other hand.

There are various bits that can be mounted, including CRATEX bits that fit Dremel that are perfect for grinding, deburring and polishing.

The downside of this method is that you'll do what is called lateral sharpening. Lateral sharpening ruins edges, as you are not sharpening the whole edge of the blade in one stroke. That's why it's more suitable for removing smaller imperfections.

If you are using this method, be ready to go back over it with a file in the perpendicular direction.

Machete Sharpening Tool #5: Sharpening Stone

What is great about this method is that it doesn't require expensive hardware, so it can easily be implemented in field conditions. It does require some effort but is generally quite easy.

It's a traditional way of sharpening a machete, and the procedure is similar as for knife sharpening on a whetstone (see more in Chapter 3). Important to mention is that there is no point in getting expensive water stones, especially if you are sharpening a cheap machete, so don't bother with that. A few easy steps to follow to get this right are:

- Place the stone on a flat surface in front of you (a good trick would be to secure it on top of a piece of wood with 4 nails – 2 in the front and 2 in the back);

- Wet the stone;

- Place the tip of the blade in the bottom right hand corner and push it forward against the stone until you've reached the left upper corner;

- Repeat while keeping in mind that there is no need to lift the machete up after you've reached the top corner to bring it back to the beginning, because the process will be too slow. Simply slide it back and forth while applying more pressure as you go forward and less as you pull the blade back (should more look like dragging). The process should be fast rather than slow;

- Rinse, clean and check the sharpness.

You can also use a whetstone for light maintenance or honing and the procedure is pretty much the same as for sharpening.

Good to Know: Machete Blade Sharpening Tip

You should always leave a part of the machete blade above the handle dull. There are a few reasons for this practice. If you are going to use the machete in the field, you'll want to use a few inches above the base as an alternative grip area, because it will shorten the handle and deliver a bit more accurate chopping action.

Also, you don't want to cut your knee or a thigh when making a huge swing, or you don't want to cut your hand in case it slips forward while getting the machete out of the sheath.

That's why you'll need to either leave a few inches of the edge unsharpened or to take a file and blunt this part of the blade after you finish sharpening it.

If you've already sharpened the blade and want to dull it with a file, follow these steps:

- Grab the blade above the base with one hand to measure the space that you're going to blunt;

- Grab a black tape roll and stick the beginning of the tape just above the base of your index finger. Wrap the tape around the blade;

- Take the file and start blunting off the part between the tape and the handle.

Maintenance & Honing the Machete Blade

After you open up the bevel with any of the sharpening methods, you'll need to hone it. A honing rod will do the trick and the procedure is the same as for honing a knife (explained in Chapter 2) - you have the "rookie" method and the more advanced method for sharpening pros.

Of course, if you feel that the sharpening procedure has left some imperfections on the edge, you can use a polishing or buffing wheel to turn that edge into a perfection. And this one is really easy: simply place the edge flat against the wheel and move across it. Once per side will be quite enough to give the blade a nice clean edge.

My Use of CRATEX

For the "My Use of CRATEX" Project, we received a million-dollar idea from our dear customer Roy, so we wanted to share with all who's machete needs some good sharpening:

"I just wish I had the ability to mass produce these and offer them for sale. This truly is one of those very simple, million-dollar ideas!"

"I glue a strip of 6" x 1" x 1/8" CRATEX oblong stick (product number Q6801-F) to a section of a paint stirring stick."

"I use this homemade sharpener to maintain a true convex edge on my parangs and machetes, that I use for bushcrafting."

"This use of CRATEX, because of the give of the rubber, is truly the easiest, most effective way, to create and maintain a true convex edge on any blade, without creating an unwanted micro edge."