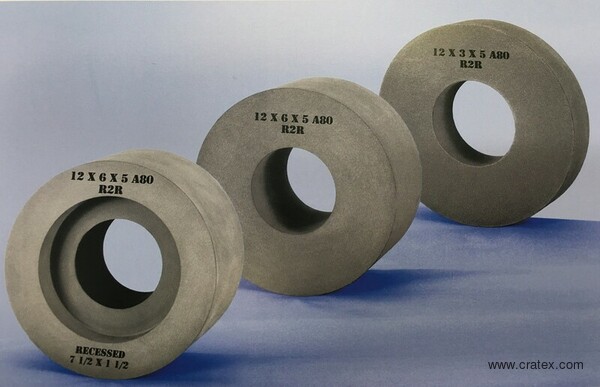

Regulating Wheels

In America, the number of actual regulating wheel producers has steadily decreased. Some who remain produce products under private label agreements. Several different rubber production processes and rubber compounds are utilized. The differences in production processes and rubber compounds determine the quantity of the end product.

In late 1997 Cratex began the production of regulating wheels utilizing the absolute best production methods and raw materials. The positive result for our efforts is a steady gain in market share. Reading further you will learn about Cratex wheels and most other wheels produced in America. We discuss the purpose of regulating and how it relates to centerless grinding.

Purpose of the regulating wheel

Regulating wheels are mounted directly across from the centerless grinding wheel. The regulating wheels' purpose is to regulate the rotating speed of the part being ground. The recommended speed of the regulating wheel is 60 to 80 times less than the grinding wheel. The result is the part being ground rotates much less than the speed of the grinding wheel which allows the grinding wheel to grind metal off the part instead of the part spinning.

Regulating wheel market information

There are only approximately 6 producers with brand name recognition. Of the 6 1/3rd are considered low quality, 1/3rd are another four brand name products available however they are NOT the producers. Understanding that there are three different degrees of quality the following information can help you to understand the differences between each.

Low-quality wheels are made from liquid rubber. The liquid rubber is poured into mixing containers. The abrasive grain is poured in just after. The container is held under the mixer and the blades lowered into the container. The mixer blades mix the rubber and grain solution for a predetermined period. The rubber/grain mixture is poured into a wheel mold. The mold is then placed into a curing oven which typically has a 24 hours cure cycle. During this time the grain has a tendency to settle toward the bottom or to one side of the mixture. The result is poor grain distribution which can cause heard and soft spots in the wheel. The performance results can be out of round parts (parts that do not meet tolerance specifications).

Medium quality wheels are made with solid calendered rubber. In this case, the rubber is a solid but poor quality. Poor quality solid rubber will not accept the grain as easily as high-quality rubber. The grain can clump during the grain impregnation operation causing hard and or soft spots. Poor quality solid rubber can be considered an improved product versa liquid rubber.

High-quality wheels are produced with expensive solid rubber. The rubber accepts the impregnation of the grain without any problems. Being solid, the grain will are medium quality and 1/3rd high quality. There not float or sag out of place during curing. high-quality wheels will not develop hard or soft spots.

Common questions

Q: Why are there low-quality wheels on the market, if high-quality wheels are available?

A: Until now high-quality wheels were SUBSTANTIALLY more expensive and sometimes are hard to justify. Also, high-quality wheels are not necessary for all centerless grinding operations.

Q: Will high-quality wheels enhance ALL centerless grinding operations?

A: NO! Typical “through feed” applications for bar stock for instance may only need low tolerance roundness measurements. In many cases, this can be achieved with low tolerance wheels.

Q: How does a quality wheel help to generate high tolerance?

A: A low-quality wheel can have hard or soft spots and when they are exposed it will change the dimension of the part being ground. The wheel will compress inward for a soft spot and not have even wear for a hard spot. In either case, you cannot hold tight tolerances.

Q: What makes Cratex a high-quality wheel other than the type of rubber?

A: Cratex manufacturing process includes a machine mix. ALL other solid rubber producers use a (manual) two roll mill station to squeeze the grain into the rubber. With this method, you rely on the operator to evenly spread the grain into the mill station over 30 times per wheel. This is impossible to control. Cratex utilizes an automatic mixer that evenly distributes the grain into the rubber in just a few minutes. This method ensures that every grain particle is evenly distributed throughout the rubber mix.

Q: What is “calendered” rubber?

A: Calendered is a word to describe the process of making rubber slabs into ring shapes for compressing into molds. Once the grain is impregnated into the rubber mix via the automatic mixers, the rubber must be sheeted to a predetermined thickness. Example 14”x10”x5” wheel requires 10 solid rubber rings 14”x10-1/32”x5”. The rubber rings are calendered (pressed between to rotating steel rollers) to thickness. The rings are then compressed into the mold and cured.

Q: Why should anyone buy a Cratex wheel?

A: Cratex offers high-quality wheels at low and medium quality wheel prices. Cratex high-quality wheels can easily be justified for low-quality wheel applications.

FREQUENTLY ASKED QUESTIONS

If any Cratex item does not perform as promised it is returnable for a full credit or exchange.

- E-mail: sales@cratex.com for return authorization number. RA number must be on the shipping label.

- All returns must be in resalable condition. Returns to include copy of original packing slip or invoice.

- Product returned after 30 days from shipment date will not be accepted.

- Cratex will offer returns for replacement product only. No cash refunds.

- Replacement value must equal to original order amount. No credit will be issued for a lesser amount.

- Customer is responsible for return freight charges.

- Replacement orders must be placed within 30 days of return or credit will be void.

Most orders are shipped in 2 business days. If we do not have the item in stock, then it is back ordered and it will take 5 weeks. You will be notified via email about your order confirmation delivery date.

In case there are any issues with your order, you will be contacted by the Cratex Customer Service Department.