INTRODUCTION

CRATEX abrasive manufacturing Company from Encinitas, CA is leading US manufacturer of grinding and polishing wheels and points for dental laboratories.

CRATEX extensive product range offers a variety of dental rubber polishers in different grit textures, sizes, shapes and length.

Specially designed for orthodontic workpieces rubber wheels and points can easily be attached to a rotary tool for trimming, pre-polishing, smoothing and fine finishing of porcelain tooth surface, retainers, veneers, bridges and crowns.

Read below and learn what the most used CRATEX products in dental labs are? Check what has to say orthodontic expert or we could say “artist” about CRATEX dental lab polishers and lathe wheels. At the end learn key points about the essential ortho/dental lab tools.

Our team will constantly update an article with new chapters so stay tune and if you like share on your favorite social network. Sharing is caring!

CHAPTERS 4

CHAPTER 1

CRATEX Products for Dental Labs

CHAPTER 2

Necessary Dental Lab Equipment to Start With

CHAPTER 3

Dental Lab Technician Salary

CHAPTER 4

Dental Lab Technician Schools

CRATEX Products for Dental Labs

CHAPTER 1

CRATEX abrasives for dental labs are made from silicon carbide – along diamond hardest abrasive available. Thus, there is no need to apply high pressure to your workpiece – choose wheel or mounted point grit size and set the high speed to get optimal results. Easily achieve desired anatomic form and remove excess material with rubber dental polisher shaped as wheel or point attached to hand rotary tool.

All CRATEX products have following grit classification (product color):

- Coarse (Green),

- Medium (Dark brown),

- Fine (Reddish Brown),

- Extra fine (Grey Green).

Why Buy Dental Polishers from CRATEX

- Unbeatable quality compared to competitors

- Fantastic durability, smooth and high precision work

- Great ROI when compared price and quality

- Rubber bond makes them damage free for workpiece

- Used and highly recommended by orthodontic technicians for 20 years

- Fast delivery across US warehouse

- Free shipping for orders above $149.

Used for:

- Shaping and trimming acrylic retainers,

- Pre-polishing, smoothing and finishing porcelain tooth surface, crown, bridges, fixed and removable orthodontics appliances,

- Decrease roughness on fixed and removable orthodontic appliances and many other.

CRATEX Small Dental Polishing Wheels

Small wheels (up to 1 inch) are most used CRATEX products in dental laboratories. Small diameter rubber wheels will help you grind, polish and smooth orthodontic workpieces. Most laboratory professionals use coarse grit wheels for cutting. For polishing and finishing operations are used fine and extra fine grit wheels. Alongside grit you need to choose wheel thickness and shape (tapered or straight) for more delicate and difficult to reach areas between implants.

Small wheels are appropriate for large surface polishing and smooth finishing of acrylics and plastic retainers, porcelain crowns and bridges, ceramic teeth and partial framework. Technician love to use CRATEX rubber polishers because they can rest assured rubber will not harm and mar teeth surface. They are very durable and long-lasting.

Contouring using small wheels can be done quickly and without excess heat. Combined with other CRATEX dental polishers, the lab technician can make teeth with correct size, shape and texture. This way you can create a natural-looking restoration that will please both - dentist and a patient.

CRATEX Large Dental Polishing Wheels

Large wheels are used with some of the dental lathes. Orthodontic technicians and dental practitioners primarily use CRATEX coarse (green) 3" wheel for trimming - a bulk reduction of acrylic for removable orthodontic appliances. These are real time savers which makes your lab more profitable.

Large wheels cut the acrylic retainer very fast so technician gets the basic shape of the retainer in just a few minutes. Using CRATEX rubber abrasive wheels risk to damage wires in retainer is reduced to the minimum. This way you will save a lot of time since the removal of bulk acrylic and contouring can be done with just one wheel. There is no need or (minimal) to use metal bur in this initial stage. There is no need to use polishing paste.

CRATEX Rubber Points

Rubber points are perfect for initial and fine polishing (depending on a grit size) of acrylic retainers, porcelain teeth, ceramics bridges and crowns and hard to reach teeth areas. All this leaving no streaks on acrylic, porcelain, ceramic, gold or metal surface.

Achieve smooth and uniform surface as well as clean and sleek edges using extra fine grit size CRATEX points.

Choose point shape (bullet point, tapered or cylinder) and size depending on the workpiece and attach on your favorite rotary tool. For pre-polishing start with medium grit and finish with fine polishing using extra fine (grey green) grit. Easily carved rubber points perfect to go under retainer wire and polish and smooth surface to almost mirror finish. Using shaped polishing points is much cleaner then pumicing and easier than using buffing wheels.

CRATEX Rotary Handpiece

Using small polishing wheels and rubber points in dental labs can be possible only with hand rotary tool. CRATEX developed rotary handpiece especially designed for orthodontic and lab technicians – CTX 800. With this tool, a technician is able to fast and easily make high precision corrections on acrylic retainers, crown, braces, bridges, veneers and removable orthodontic appliance.

Lightweight with special ergonomic design, a body made from aluminum and steel it is capable to produce high speed and torque making the very low level of noise.

Vibrations are reduced to a minimum allowing technicians to work for hours without fatigue in wrist or hand.

CRATEX Polishing Kits

If you are in doubt and need some real action to feel and decide what CRATEX products are right for your dental lab than here is the answer. Try one of CRTAEX mini kits at a bargain price. Recommended for the dental techs is Mini Wheel Kit No. 107. Kit includes 10 different wheels and two mandrels. For $36,58 (shipping included in the price) you have the opportunity to feel CRATEX rubber polishing wheels in action.

Necessary Dental Lab Equipment to Start With

CHAPTER 2

Dental lab technician is vital part of dental care team. They are responsible for fixed and removable restorations - but easiest way to define this career is to say they create replacements for natural teeth. There are several certifications in different areas dental technologist can acquire: orthodontic, dentures, implants, ceramics, crown and bridges.

Some say this profession is an art and a science at the same time. But more than everything it is driven by latest technology in medical field. In this chapter we need to introduce tools every dental lab has. Let’s start with basic ones.

Dental Laboratory Furniture

Dental lab furniture consist from lightning system, seating chair and benches in most cases. Combination of those three with addition of dust collectors and drawers can be optimal solution both for small and large dental labs - and it is called dental lab workstation.

There are great number of different types of workstations on the market. Price mostly depend on workstation size (meaning it is one or two seater), used materials, bench surface, number of drawers, dust collector speed and power and light type.

Modern dental workstations are made from electro-galvanized stainless steel and have modular seating position with arm rest. Lights can be controlled in several levels and modes depending on external light source. Drawers come in different sizes, colors and capacity. Some manufacturers offer height adjusted top surface. This option can dramatically improve ergonomic. Work surface is made from solid materials that can last for decades and in different colors.

Price for new dental workstation can reach several thousand dollars. That’s the reason many dental lab owners choose to purchase used dental workstation. Search online and you can find second hand workstations in great shape at discounted price.

Most trusted manufacturers and suppliers in this field are KAVO, Aries, DentalArt, NevinLabs, Amtech, Lista etc.

Dental Lab Rotary Handpiece

Handpiece is essential tool in every dental lab. It is impossible to produce dental and orthodontic appliance without quality handpiece rotary tool. Here should point that lab rotary tool is not the same tool as high speed dental drill or bur for removing decay.

Lab rotary tool has vast spectrum of usage and combined with bur or small abrasive wheels and points can trim acrylic retainers, pre-polishing and fine polishing all kind of dental and orthodontic workpieces like retainers, implants crown and bridges, cut and sprue sectioning, finish fixed metal orthodontic appliance - micro etching, cleaning, smoothing and buffing.

What to look after when buying dental lab rotary tool? Depending on lab needs and application you can pay attention to torque, RPM range, motor type and size, hand or foot control, weight, shape, number of accessories, cooling, noise level, chuck size and type and of course there is always warranty period.

Today’s dental handpieces are made from premium materials like steel alloy. Thea are robust and very light at the same time. Speed range goes from 1000 to 50,000 RPM with smooth power delivery and responsiveness. Reverse speed usually goes from 1000 to 5000 revs per minute.

Shape and dimensions of tool is something that needs to be considered as well. Working for hours on delicate pieces using just one hand can be hard. Anatomical shape will improve maneuverability reducing pain in palm area.

There is great number of suppliers and manufacturers, just to name some: CRATEX, Vacalon, Aseptico, KAVO, Buffalo Dental, W&H, Dentsply Sirona, NSK and many more. Prices can vary depending on specification, from $200 up to $2000 with accessories.

Dental Lathes

Dental lathe looks like ordinary bench grinder and it is used with abrasive attachments for polishing and finishing dental and orthodontic appliance. Polishing lathes are used in many industries like jewelry, lapidary, woodworking, metal working and of course dental. Choose polishing lathe for your dental lab according to your daily tasks, don’t buy to powerful lathes if you don’t need them. This way you will stay within budget and save space in your laboratory.

How To Choose Dental polishing Lathe

Dental lathes are primary used for polishing, grinding, cleaning and brushing plastic and metal materials. There are a lot of features that you need to take into consideration when choosing one. Common things to check here are: electric engine power, speed, single or double spindle station, and noise level, does it have protection or shield, light and removable dust filters.

Another but not less important thing to decide is do you need polishing lathe with vacuum cleaner. Vacuum cleaner is great addition and will effectively collect dust when working on plastic, cement or acrylic molds. If your polishing lathe don’t have option to add vacuum cleaner you can always attach dust collector with filter. These portable collectors can collect dust and debris down to point five microns in size.

Dental lathe prices start from around $400 and can go up to $2000. There is lot of used models for sale online but you need to be cautious. Polishing lathe is essential tool in every dentist lab and needs to be powerful enough, quiet and without vibrations. Trusted brands in this field are: Red Wing, Buffalo, Wells, Erio, Dentalfarm, Aries, Obodent, Zubler, CATO, WasserMann, Sirio Dental and many other.

Dental Lab Lathe Infection Control

Polishing lathe in dental laboratory needs to be clean and disinfected to avoid dental and orthodontic workpieces cross contamination. Using rotating abrasive wheels, points, cones, burs on large number of dental appliances can increase level of dangerous microorganisms that can lead to infection. That is why dental technicians need to take extra steps in infection control to prevent lathe, prosthetic appliance and their self’s from infectious organisms.

Few steps for dental lathe infection control:

- Hand hygiene – no need for further explanation,

- Personal protective equipment – always use glasses, gloves and masks when working on dental lathe

- Polishing lathe protective equipment - it is also recommended to have shield placed in lathe which limits number of flying debris. Vacuum cleaner or dust collector attached to the machine while working can

- Disinfection or sterilization – keep clean rotating lathe pieces like abrasive wheels, stones and burns. Same goes for items processed on the lathe.

Dental Lab Technician Salary

CHAPTER 3

Dental lab technicians are the guys you probably won’t see when you go to the dentist to try your new crown. While they are not patient-facing, their job is crucial and the most important one for having a comfortable implant or natural-looking restoration.

How Much Money Does a Dental Lab Technician Make?

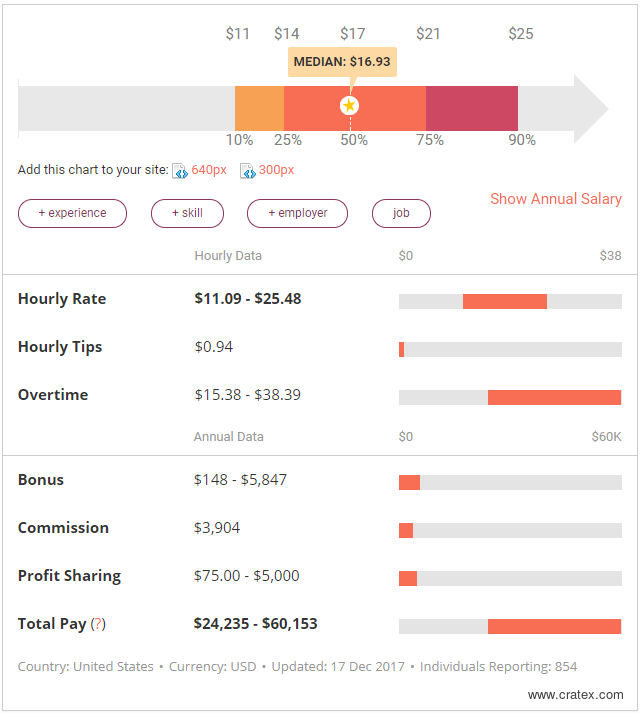

Ask Google about an average dental laboratory technician salary and you’ll be shown info from PayScale – average dental lab tech in the US makes around $17.41 per hour. Almost the same salary figures come from Indeed. These numbers are in general and way too broad since payroll can depend on experience, the degree you hold, state and few other factors.

Let us crunch all variables and show you the determinant factors of a dental lab technician salary.

Job Statistics & Summary

- Job satisfaction - 80%

- Gender structure: female 42%, male 58%

- The largest employers –Commercial dental labs, medical equipment and supplies manufacturing, healthcare stores and offices of dentists

- Entry-level education & academic requirements – High school

- Job demand – High. Projected growth is 13% (from 2016 to 2016). Average growth for all occupations in the US is 7%

- Job outlook & prospects – Good

- Work schedules – Mainly full-time job

- The most required skill for this occupation: Precision and attention to details

- Recommended experience - Minimum 4 years for fully trained dental lab technician.

Average Salary

What is the average pay for a dental lab technician? It is hard to say with 100% accuracy since different sources offer different numbers. But if you manage to combine all data available online you can have a decent perspective about an average earning per hour and annually.

Factors that influence earnings for technicians are:

- Location (State),

- Experience and skill level,

- Degree and certificate,

- Self-employment (business owner),

- Lab size (number of employees),

- Bonuses and overtime pay.

The most important is the location of a laboratory. Be careful if you are looking to increase your earning moving to another state. Always calculate the cost of living before you decide to move and look for a job opportunity in another state.

After Geo location, there comes experience and skill level. The difference in average hourly wage between the least experienced and the most experienced technician can be more than $15 for those who work in laboratories with 25 or more employees.

If you decide to run the laboratory on your own, your average hourly wage will be higher that is for sure. But you need to be prepared for many expenses from the very start. You’ll need to buy dental lab tools and equipment. Read previous chapters to learn more about dental lab tools and CRATEX tools for dental technicians. You also need to calculate tax and business insurance that you will need to pay by yourself.

According to National Association of Dental Laboratories average salary in small and medium-sized labs are higher compared to those at large labs with more than 25 employees.

Degree and certificates are self-explanatory. If you hold several certificates it is more likely that you have a wide knowledge spectrum that makes you capable to successfully complete the most advanced orthodontic and dental projects.

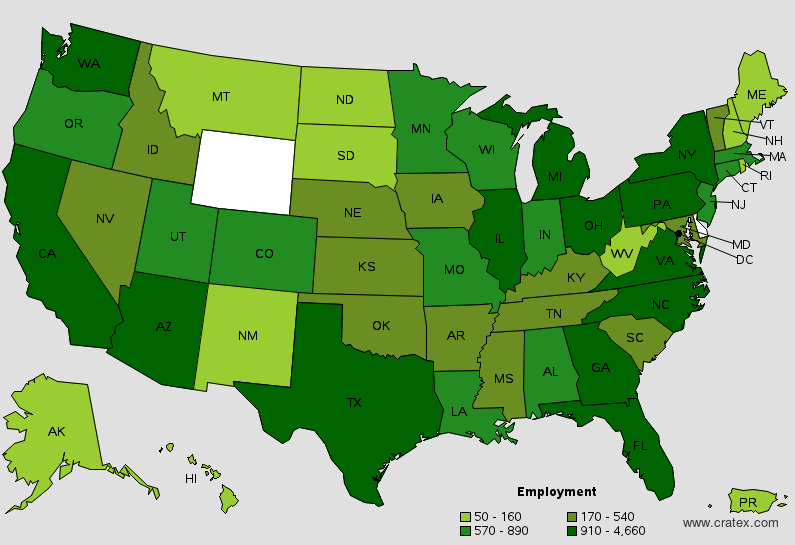

Dental Lab Technician Salary by State

According to the survey from May 2016, states with the highest employment rate in this occupation are California, Florida, Texas, New York and Pennsylvania.

Same research from Bureau of Labor Statistics shows that states with the highest salaries for dental lab technicians are: District of Columbia, Alaska, New York, Vermont and Rhode Island. See table below for dental lab technician salary by state.

| State | Hourly Wage | Annual Wage |

| District of Columbia | $37.70 | $78,410 |

| Alaska | $25.50 | $53,030 |

| New York | $23.28 | $48,420 |

| Vermont | $22.67 | $47,150 |

| Rhode Island | $22.63 | $47,060 |

Dental lab technician salaries are the highest at offices of dentists followed by commercial dental laboratories and medical equipment manufacturing.

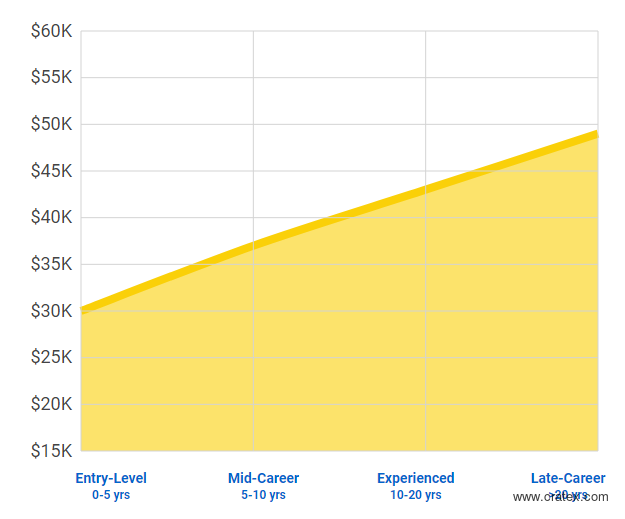

Dental Lab Technician Jobs Salary by Experience Level

Based on a research (PayScale.com) conducted on more than 250 salaries provided by anonymous users, pay by experience for dental lab technicians has a positive trend.

Experience plays an important role in this research from 2015 by NADL. Technicians with 20 years of experience (or more) can almost double their annual wages compared with the time when they had to beg for a career. at the begging of a career.

How Do You Become a Dental Lab Technician?

If you liked the numbers above and you find this occupation interesting start looking for a good education in this field. There are some great schools for dental lab technics in the US. If you want to learn more about them, read our next chapter.

Jobs for Dental Lab Technicians

If you are just about to start your career as a technician in the dental laboratory and looking for some good jobs start from an online search. Search the Internet for “dental lab technician job openings” and you’ll get decent job opportunities on the websites like Indeed, ZipRecruiter, Monster or SimplyHired.com.

Resources

http://www.ada.org/en - American Dental Association

http://www.adea.org/ - American Dental Education Association

https://nbccert.org/homepage.cfm - National Board for Certification in Dental Laboratory Technology

https://nadl.org/home-page.cfm - National Association of Dental Laboratories