Engine Turning Abrasives | CRATEX Abrasives

This article is part of cratex engine turning sticks series.

For full article click here

CRATEX abrasive manufacturer from California US offers a wide range of 6 inches length sticks perfect for engine turning available in following diameters 3/16”, 1/4”, 5/16”, 3/8”, 1/2”, 5/8”, 3/4”, 7/8” and 1” and the choice depends on the and the desired diameter of the spin.

Depending on the kind of metal that engine turning is applied on you’ll need to choose appropriate stick grit. CRATEX rubberized sticks are made in four grit textures:

1. Coarse (C) - steel

2. Medium (M) – for stainless steel

3. Fine (F) – for aluminum

4. Extra fine (XF) – aluminum and other softer materials.

Sticks are rubber bonded and made of purest silicon carbide. See below grit colors.

The appropriate grit depends on the type of the material that you’re working on, and it’s important to choose the right one that could cut enough to eliminate the previous swirl (i.e. that could avoid ghosting). For example, we can recommend the medium grit for aluminum, and coarse grit for stainless or other types of steel.

1/2" Cratex stick - Medium grit - it gives pretty good coverage with minimal ghosting. Long lengths in the press "wobble" too much. I will need to make a mandrel to hold short pieces. Chucked a short scrap in the press and got OK results from it, tried some WD40 for lube since it was the first thing in the flammable cabinet and the swirls came out VERY uniform and clean!

My verdict? I am going to order some 1/2" and 1" Cratex for the various parts I need to do. I am VERY HAPPY with the results! - Tman, SD

Engine Turning Kit

CRATEX engine turning abrasives can be bought in bulk, and as a single stick as well. In case you are looking for an engine turning kit, we highly recommend Mini Kit 128S for trying out different grits. Shipping and handling are included in the unbelievable price offer and the kit includes one stick for every grit.

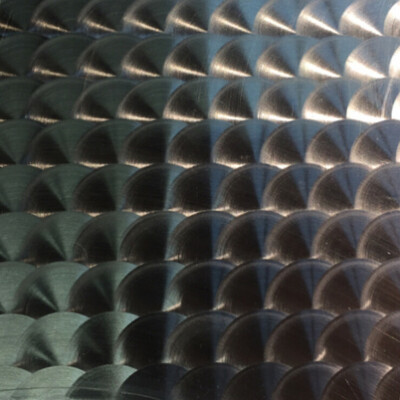

Engine Turning Aluminum With CRATEX Rod

@nemomatic Thanks to the miracle of time lapse video, you can experience what was an incredibly long and grueling studio day in just one minute. "Engine turning" sheet metal, I've learned, is something you shouldn't do. It's a drag. But I'm pleased with how my home made drill press rig worked out. The effect is really cool, and you don't usually see it on such large panels (now I know why). I still have to do the other panel, but it'll have to wait for my old bones to stop aching first.